Machinery

Innomatix has a modern workshop, equipped with a young and performant machinery fleet. We use edge technologies for fabrication, and we comply with almost all applicable codes and standards.

Software

We have the capability to seamlessly import a variety of 3D drawing formats into our software. We work with Solid Works and HyperMILL, where both 2.5D, 3D, and 5-axis milling and mill-turning can be programmed perfectly and precisely. By simultaneously milling in 5 axes, the complexity of the pieces can be increased. Our CAM package also includes Probing, ensuring greater process control and higher accuracy.

Because the job preparation is fully computer-supported through virtual machining, programming is done offline, so the machines do not have to stop for programming. The machine loading via the HS Flex and the robot loading also ensures that the machines can be used more efficiently.

Our machines

Wire EDM ROBOCUT aC600iC

The multipurpose wire-cutting machine.

Dimensions

- X-Y axis displacement: 600 x 400 mm

- U-V axis displacement: 200 x 200 mm

- Z axis displacement: 410 mm

Hermle C 250, 5-axis machining centre

Our milling machine is equipped with a zero-point clamping system. So we can quickly and efficiently set up our clamps to produce your parts.

Dimensions

Traverse path: 600 x 550 x 450 mm (X,Y,Z)* Spindle Speed : 18000 tr/min

Control Heidenhain TNC 640

External tool magazine

Tool holder HSK A63

Renishaw 3D probe and BLUM tooling and fracture control

Hermle C42 UMT

The Hermle C 42 UMT machining centre is a high-performance milling and turning centre.

Dimensions

Traverse path: 800 x 800 x 550 mm (X,Y,Z)

Spindle Speed: 15000 tr/min

Control Heidenhain TNC 640

External tool magazine

Tool holder HSK A63

Renishaw 3D probe and BLUM tooling and fracture control

Handling System HS FLEX Heavy

The HS Flex Heavy is a flexible pallet automation. In combination with a large tool magazine, it ensures a high degree of flexibility to schedule and combine various tasks. The combination of 5-axis milling and turning also provides numerous possibilities.

Brother S1000X1- CNC Vertical Machining Center

Dimensions

Traverse path: 1000 x 500 x 300 mm ( X,Y,Z)

Spindle Speed : 16000 tr/min

Tool holder of Spindle Taper: BT30

Tool Magazine Capacity : 21 ATC

INTEGREX i-350H ST

With the integrex machine, parts up to a turn diameter of 670 mm with a maximum length of 1500 mm can be processed.

Dimensions

Travel: Max diameter 400 mm and max workpiece length of 1350 mm.

The machine can also perform 5-axis simultaneous work.

The main and sub spindle have a max speed of 400 rpm.

The upper turret has a max speed of 12,000 rpm (a full-fledged milling head).

Tool magazine equipped with 112 tools.

All this combined with a RoboJob Tower for automating and ensuring 24/7 production with automatic loading and unloading.

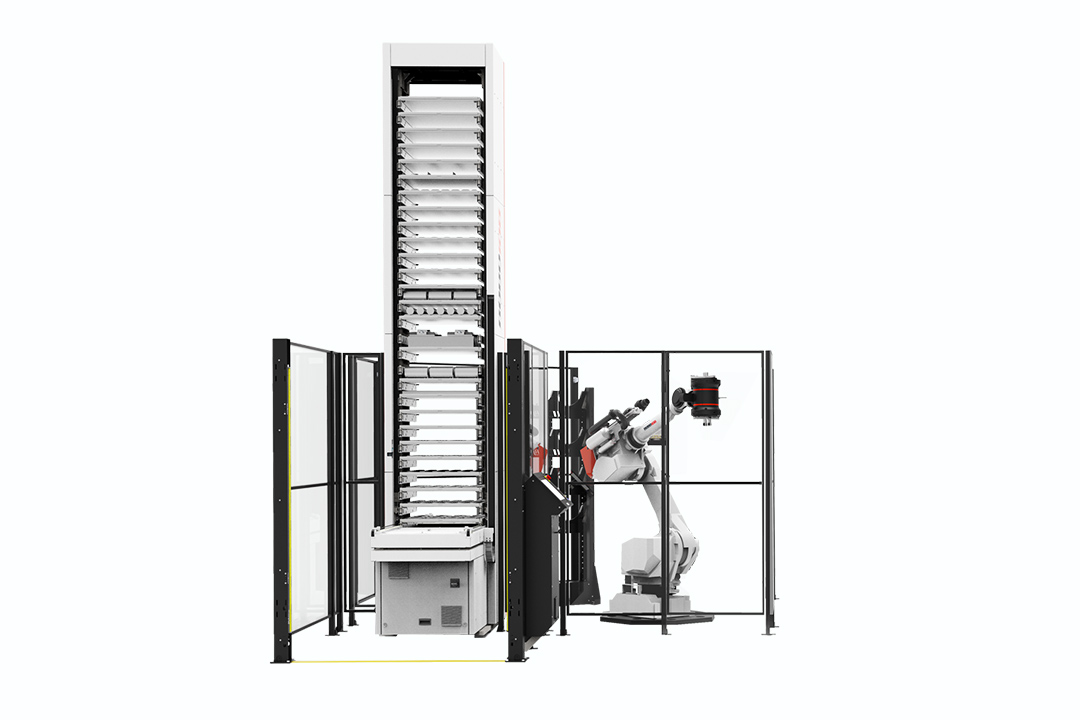

Robojob Tower

A revolutionary total solution for the loading and unloading of the CNC turning lathe, milling machine or turning/milling combination.

- Single pieces to large runs

- Exchange of clamping devices

KASTOwin A 5.6

- Cutting range: 560 mm

- Smallest dimension to be cut: 10 mm

- Shortest length of residual piece, automatic operation: 35 mm

- Shortest length of cut-off piece: 10 mm

- Cutting range flat height x width: 560 x 560 mm

TRYMA TM-600-A

- Automatic 1-head sawing machine with saw blade Ø 600 mm for aluminium and plastic.

- Automatic rising saw blade Ø 600 mm

- Vertical and horizontal pneumatic clamping

- Pneumatic lubrication of saw blade

- Swivelling work table for angle adjustment

KASTOecostore bar stock

Thanks to the KASTOecostore warehouse, we have the opportunity to closely monitor our stock management by digitizing it.

We also have the ability to keep a full range of basic materials in stock for you, enabling us to supply quickly and efficiently.

MAZAK QuickTurn 200MSY

High Performance for demanding workpiece applications.

Dimensions

- Center distance: 500 mm

- Main spindle speed: 5000 rpm

- Sub-spindle speed: 6000 rpm

- A bar feeder is connected to the machine (see attachment).

- Powered tools and Y-axis.

Wondering what Innomatix can do for you?

Contact us for tailor-made advice.