Realisations

Vacuum molds

We proudly present some high-quality vacuum molds that we have manufactured using our advanced Hermle C42. By employing 5-axis milling strategies, we were able to produce these molds with precision and efficiency.

These techniques allow us to integrate complex shapes and details, which are crucial for the functionality and reliability of vacuum molds.

5-Axis work

We also offer smaller 5-axis machining projects, thanks to our versatile Hermle C250. This high-performance machine enables us to produce complex components with great precision and flexibility.

5-axis machining provides numerous advantages, such as creating intricate geometries and reducing the need for multiple setups, ensuring more efficient and accurate work.

Small turning work

With the addition of our latest acquisition, the Mazak Quick Turn, we have expanded our machine park to offer even greater versatility.

This advanced machine now allows us to provide precise and efficient small turning work. Think of finer machine components essential for various applications. The Mazak Quick Turn enables us to create complex designs with high accuracy, perfectly positioning us to meet our customers’ specific requirements. Here are some examples of high-quality machine parts we have manufactured using this technology.

High-Quality products

For a renowned machine builder, we realized several high-quality products.

One of the products we developed is a Y-connector, playing a crucial role in efficiently connecting different components within complex machines.

The second product we created is a vacuum block. Our team worked on developing a vacuum block that is not only robust and efficient but also perfectly aligns with the machine builder’s technical requirements.

Unique pieces

For these products, we made full use of the capabilities of our Hermle C42UMT. Combining turning and milling processes, we produced each component with precision and efficiency.

The first product is a mold we made for a client specializing in fence installation. This mold is used to firmly drive posts into the ground—a critical part of their workflow.

The second product is something we are particularly proud of: a motor wheel. This wheel started as a solid square block and was entirely custom turned and milled using the Hermle C42UMT. The result is a highly technical product that perfectly reflects our expertise and precision.

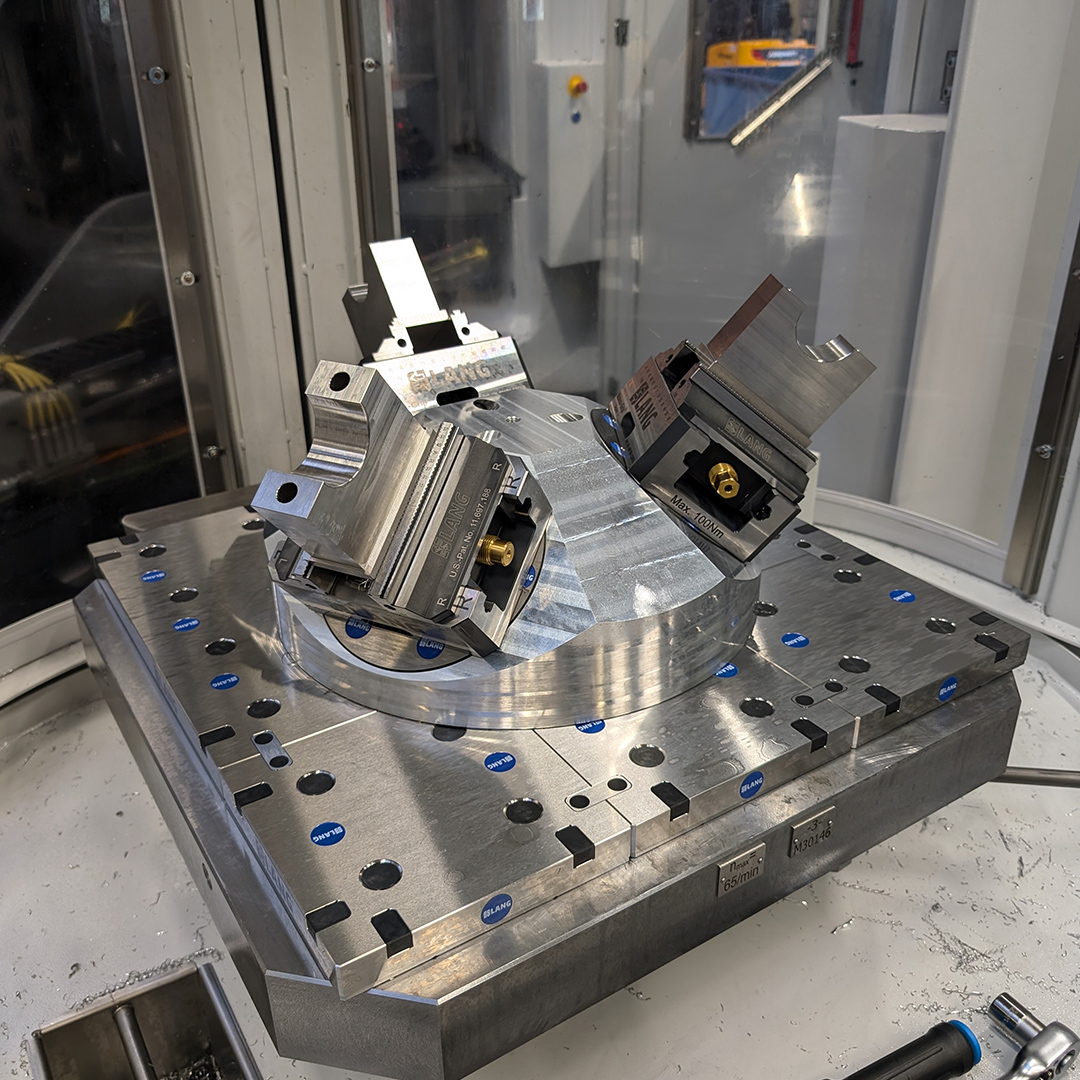

Applications with LANG Zero-Point clamping system

Pallet of our HS Flex equipped with the LANG zero-point clamping system. A pyramid was mounted on it to work more efficiently.

3-Axis milling work

It doesn’t always have to be 5-axis milling work. With the help of our Brother S1000X1 milling machine, we can also provide 3-axis machining projects.

Applications with HWR chuck

This product was manufactured on the Integrex. After turning, we performed an additional operation on our Hermle. Thanks to our HWR chuck, we can easily clamp and process this workpiece.

Wondering what Innomatix can do for you?

Contact us for tailor-made advice.